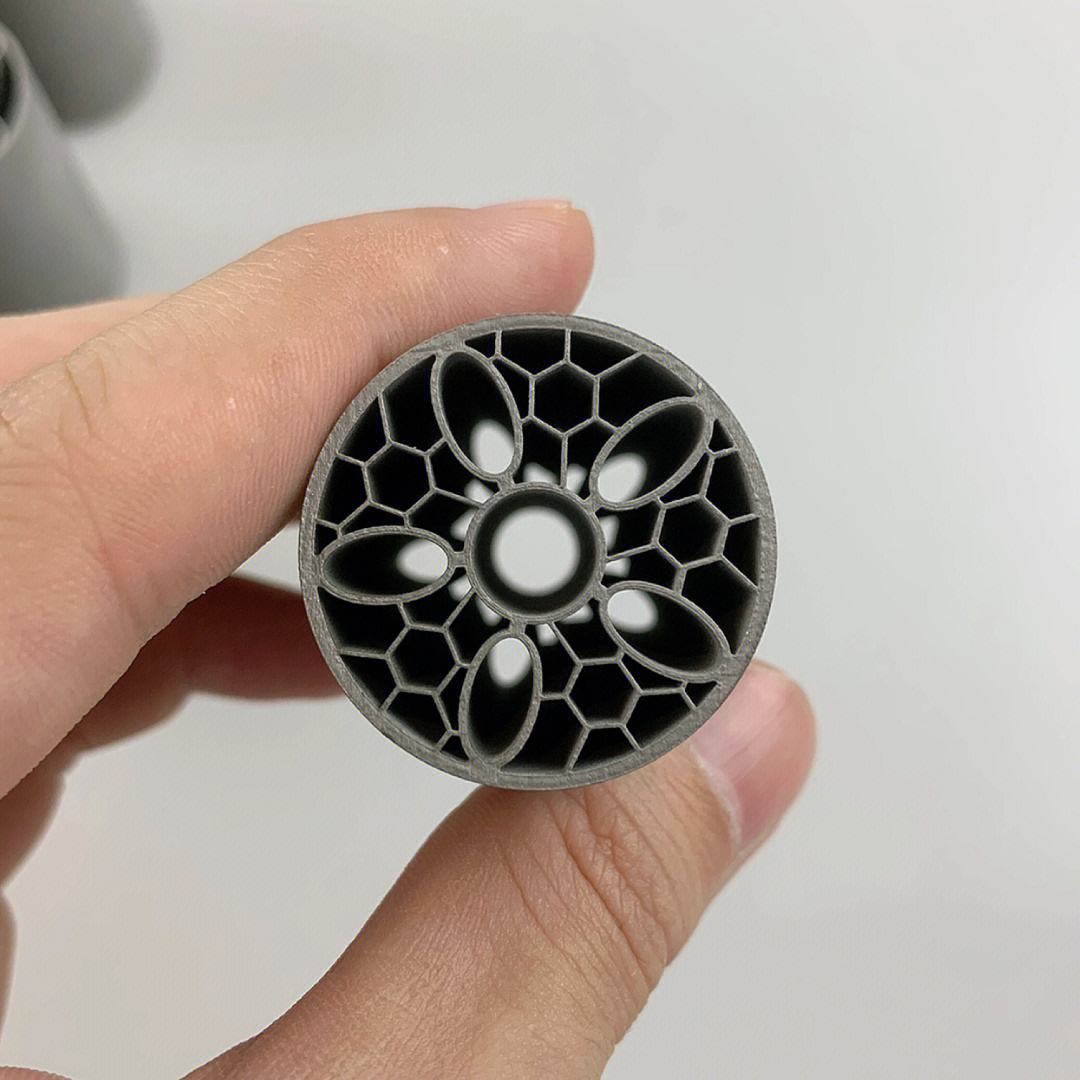

- The advantages of Pangu Intelligent Manufacturing's metal 3D printed drone accessories Lightweighting and structural optimization The fundamental goal of the structural design of unmanned aerial vehicles (UAVs) is to ensure that they have sufficient strength and rigidity during flight, can withstand various loads and environmental conditions, and possess good aerodynamic performance and controllability. The Pangu Intelligent Manufacturing technology team has adopted metal 3D printing technology to optimize the topological structure, achieving lightweight and weight reduction of the rack and structural optimization. This not only enhances the flight efficiency and stability of the unmanned aerial vehicle (UAV) but also extends its endurance, which is crucial for long-duration and complex tasks. 2. Integrated forming Pangu Intelligent Manufacturing's metal 3D printing can directly achieve the integrated manufacturing of unmanned aerial vehicle racks without the need for molds. For the overall combined manufacturing of multiple parts of the rack, the number of parts is reduced, the manufacturing process and cycle are shortened, the quality risk is lowered, and the overall reliability of the unmanned aerial vehicle rack is significantly improved. Meanwhile, the rapid conversion from design to finished product has greatly shortened the R&D cycle, accelerated product iteration and reduced production costs.

- 3. The design is free and flexible The metal 3D printing technology of Pangu Intelligent Manufacturing enables designers to freely exert their creativity, achieving rapid prototyping and production of complex designs, as well as personalized and diversified customization of various complex structures and fine products. This flexibility enables drones to quickly adapt to various specific requirements, such as operations in special environments or customized payload requirements. 4. High material utilization rate Aluminum alloy has become one of the main materials for unmanned aerial vehicle frames due to its advantages such as light weight, high rigidity, high strength, good corrosion resistance, good fatigue performance, good processing performance and low cost. Compared with traditional subtractive manufacturing processes, Pangu Intelligent Manufacturing's metal 3D printing, as a near-net-shape forming technology, generates almost no waste.